Introduction SBOBET Sport has established itself as a premier platform for football betting enthusiasts,...

In the dynamic world of online fashion retail, The Outnet UK stands as a...

Understanding the Basics of Personal Loans What is a personal loan? A personal loan...

In the realm of video game development, few companies have made as seismic an...

Assistive technology plays a crucial role in enhancing the quality of life for individuals...

In today’s fast-paced world, prioritizing health and fitness is more important than ever. With...

In a world where hectic schedules and sedentary lifestyles often take precedence, prioritizing health...

In the realm of interior design, home decor isn’t just about arranging furniture or...

Helicopter parenting, a term coined in the 1960s, refers to a style of parenting...

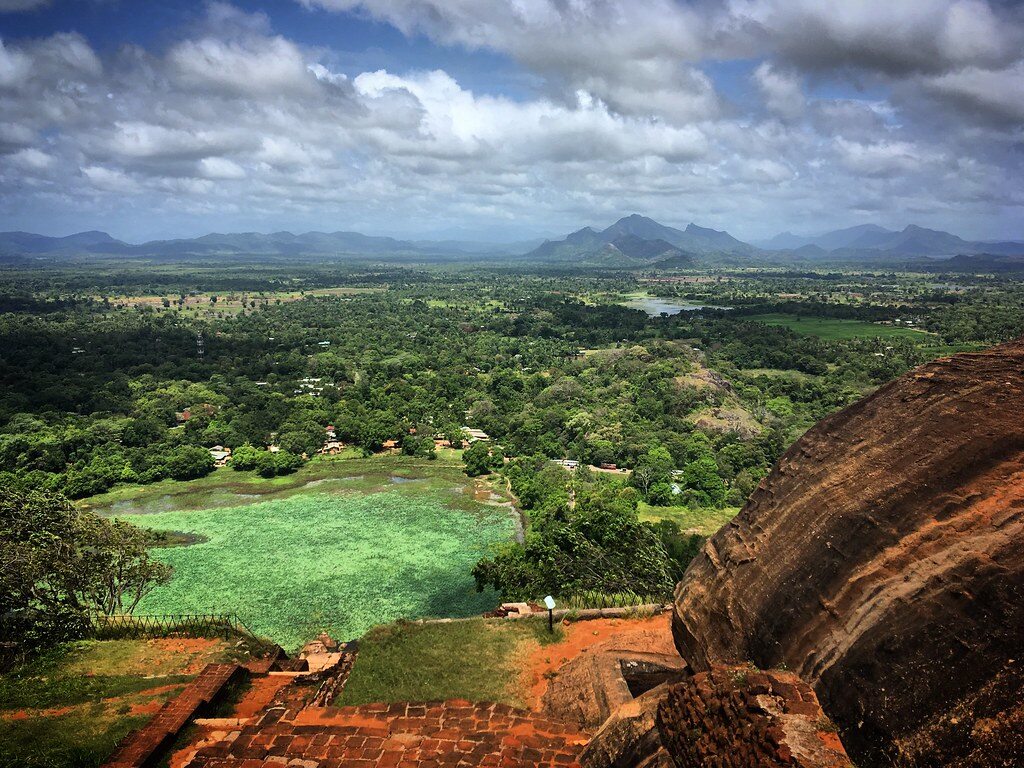

Introduction: In an era where wanderlust is embraced and exploration is celebrated, travel credit...